Sustainability

- Home

- Sustainability

Installed capacity

0

GWH

Tons estimated waste treated annually

0

+

Tons estimated fertilizers produced annually

0

+

Tons Of CO2 Captured

0

+

Sustainability

Let’s talk cows

It’s a paradox! The world craves clean energy sources to fuel the sustainable transition, while food waste is burned or left to rot, manure and wastewater pour into our rivers and oceans, adding to our already daunting environmental crisis.

It’s time we recognize what biological waste can do for local and global communities. How we can go from the problem of drowning in bio-waste to opportunity: how to make communities (energy) self-sufficient in every corner of the world.

Inspired by nature

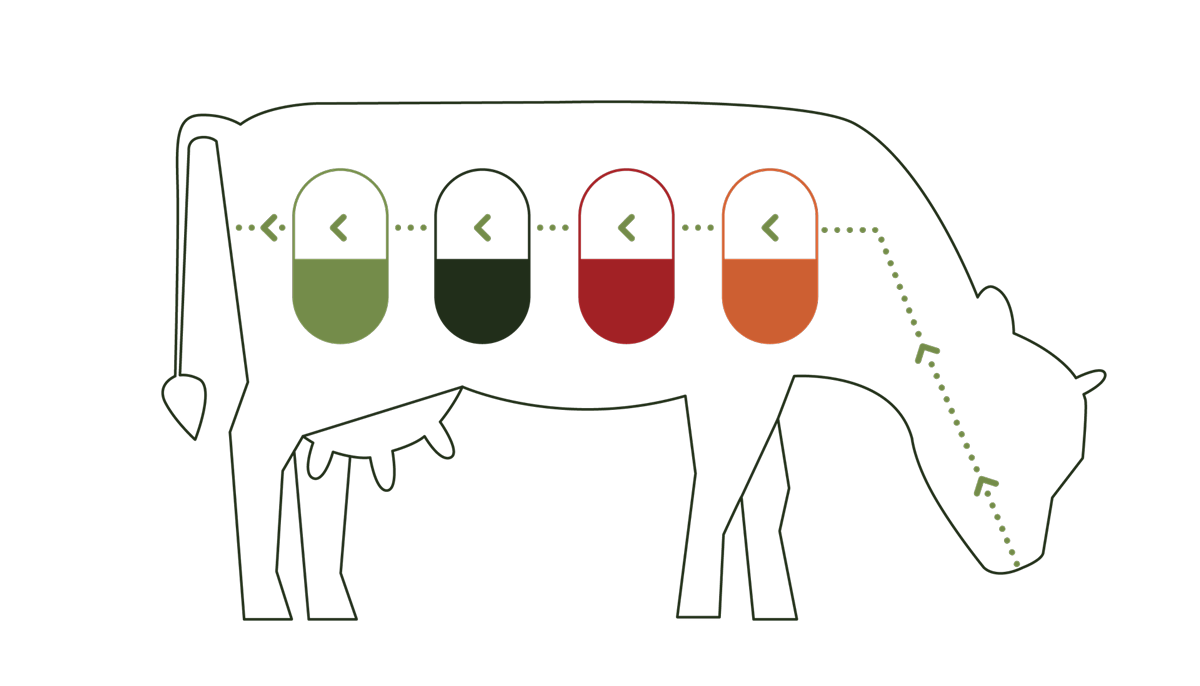

When the cow only spends 2 days breaking down food and converting it into energy, we thought it was unnecessary for traditional biogas reactors to spend up to 30-40 days on the same process.

Our bio-technology is inspired by the world champion in effective energy conversion – the Bos Taurus, commonly known as the cow.

You may ask what cows have to do with renewable energy. Everything, we say. For about a decade, we’ve been designing and perfecting a process that treats biowaste in the same way in which cows digest food.

By mimicking nature’s own wonders, our bio converters take care of the energy and scarce nutrients that are present in organic matter, and efficiently turn them into rich resources we need to build a sustainable future.

Wealth, not waste

To us, there is no such thing as wasted biowaste. We see an infinite loop of valuable bioresources.

We want to enable people to tap into their community’s bioresources, so they can fertilize their lands, power their homes, fuel their vehicles and enjoy prosperous lives on a healthier planet.

We exist to create our renewable future, one community at a time.

Circularity at heart

Renewable energy from waste. It is the perfect solution to two big problems the world is facing: the growing waste pile and the energy crisis. What are the circular benefits of the Antec method?

All organic waste is degradable

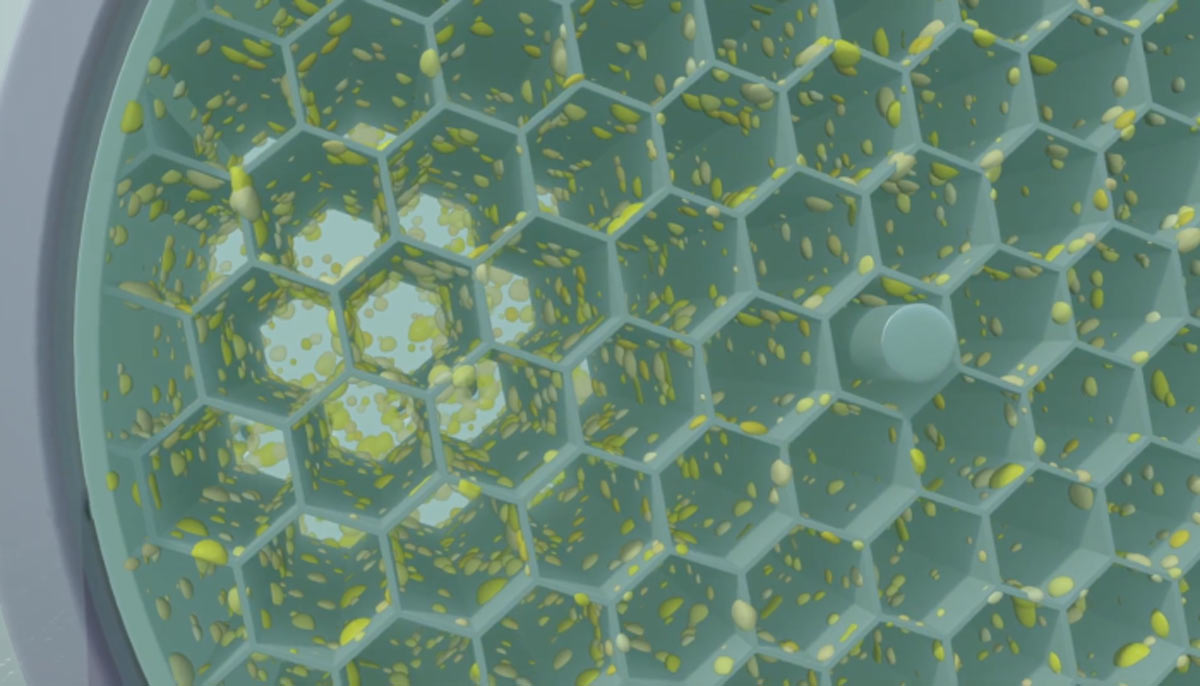

We create an ideal biomass combination for the mixing tank with the customer based on available biomass. Antec’s innovative renewable energy reactors perform best when the dry matter content is between 5 and 15%. We encourage local biomass collection and storage in various buffer tanks for various types of biomass.

In the renewable biogas reactors, the biomass is then combined, heated, and distributed. New biomass is pumped into the reactors every hour, and the treated biomass is stored in the digestate tank for 7 days, depending on the kind of substrate. The renewable biogas is collected at the reactor’s top and transferred to be desulphurized, dried, and upgraded to the necessary quality. The biomass injected into the biogas reactor is almost methane-free, odorless, and may be utilized as a top fertilizer by farmers who require nutrient-rich soil.

Renewable biogas, green CO₂ and biofertilizer

Methane is eliminated from the organic material during digestion. Before being converted to green energy, the renewable biogas is extracted from the reactor and dried and cleansed of impurities.

Renewable biogas is used to generate power and heat by passing via a gas engine, where its cooling water is warmed and can be utilized for heating. Biogas is converted to fuel in bigger facilities. Biogas, whether compressed (CBG) or liquid (LBG), is the fuel of the future for heavy vehicles, construction machines, and boats.

During the production process, CO2 may be captured and converted into green CO2, which can then be used in greenhouses for food production. Sales of upgraded biogas and CO2 are critical revenue sources for profitable biogas production.

More valuable products

After extracting gases for various uses, one is left with a mass known as “bio residue” or “biofertilizer” in technical terms.

Biofertilizer, which has qualities comparable to animal dung, can be used in organic farming. It improves soil nutrition and hence minimizes the demand for fertilizers. Furthermore, carbon is stored in the soil.

Norwegian biogas plants produce up to 600,000 tons of liquid biofertilizer per year, which can be used directly in agriculture or as a component of commercial fertilizers, compost, or garden soil.

Aligned to the SDGs

Target 7.2

Target 11.6

Target 12.2

Target 13.2

Tackling the waste problem

The world generates 2.2 billion tons of municipal solid waste annually, with organic waste representing about half. Conservative estimates indicate that at least 33 percent of that is not managed in an environmentally safe manner. By 2030, the planet will be generating at least 5bn tons of organic human and animal waste each year.

Ensuring energy security

Modern renewable bioenergy is an essential source of renewable energy, and its contribution to final energy demand is five times higher than wind and solar photovoltaic combined.

Cutting carbon with biofertilizer

The renewable biogas obtained in the biogas production process helps return organic carbon into the soil and reduces the demand for the carbon-intensive production of mineral fertilizers.