Projects

- Home

- Projects

Build, Own and Operate plants

Vest Biogas

Hornindal, Norway

The plant will process about 100,000 tonnes of biowaste per year and will be Norway’s most advanced renewable biogas plant using Antec’s technology. Cow manure, fish sludge and industrial food waste will be the primary inputs for the production of renewable energy. For shipping and heavy transport, the renewable biogas will be converted to liquified biogas (LBG). The CO2 that is captured from the plant will be made available for purchase by the food industries. Nutrient-rich biofertilizer will be returned to the local farmers as a replacement for artificial fertilizers which are beming more expensive and less accessive.

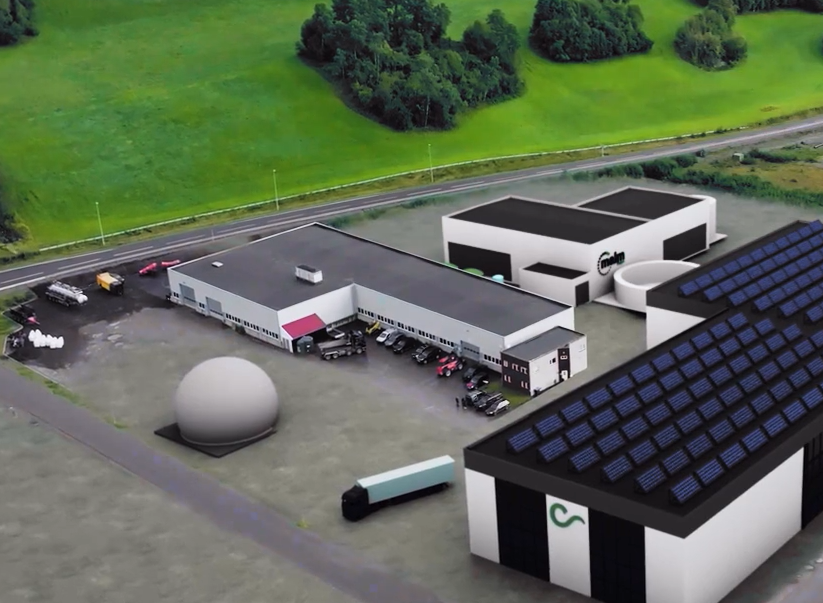

Malm Biogas

Steinkjer, Norway

The Malm Biogas Plant will be situated adjacent to Salmar’s smolt facility at Tjuin, Norway, occupying a regulated plot of around 20,000 square meters secured by a call option. Currently, there is an ongoing FEED involving all relevant stakeholders to prepare the project for FID. The primary feedstock for the plant will be provided through a partnership with Salmar, one of Norway’s major salmon producers, and local farmers in the surrounding areas. Nippon Gases, a notable European industry gas company, has committed to off taking the total CO2 volume produced by the plant. The biogas plant is designed to have an annual capacity of 100,000 tons of biowaste. This initiative aims to contribute to sustainable energy practices in the region.

R&D Projects

Plants using Antec Technology

AD System: 10 Antec BioReactors

Feedstock: fish silage and sludge, food waste, manure

Production: LBG, Liquid Bio-CO2, BioFertilizers

Startup: 2022

Location: Norway

Large - scale Industrial biogas plant

Norway, est.2022

This plant processes over 50,000 tonnes of biowaste

per year and uses Antec’s technology. 10 BioReactors are placed inside the hall, and create quiet, clean and odor – free working environment in the area, exposed for rough weather.

Small - scale Industrial biogas plant

Norway, est.2020

This plant is the first commercial plant, where Antec used existing infrastructure at the industrial site to transform a warehouse into an efficient biogas facility. 3 Antec reactors are placed inside to allow for safe and comfortable operational conditions , also to protect against snow storms and strong winds typical for this area.

The plant is designed to handle a mix of manure, fish waste from the factory and municipal organic waste from all the

county.

The facility is equipped with a foodwaste reception hall and a CHP unit for production of electricity and heat used locally.