Solution

- Home

- Solution

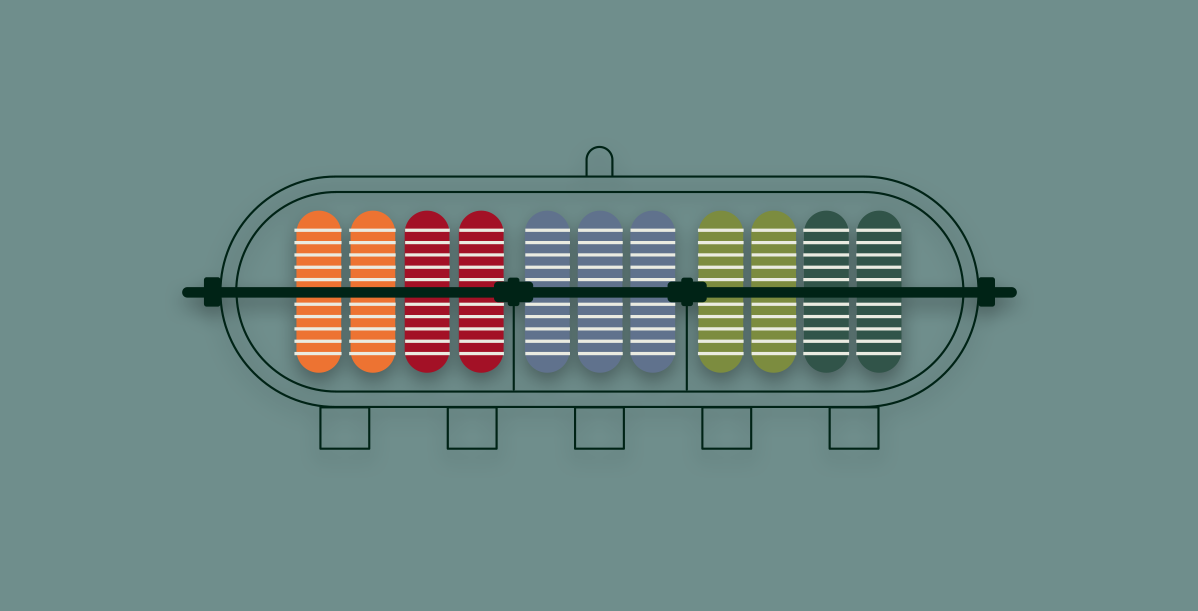

Combining the strengths of two powerful technologies

Biofilm

- High biomass density

- continuous fermentation

- high production rates

- low risk of washing out bacteria

- operational stability

- operational flexibility

Plugflow

- reduced retention time

- steady-state operation

- no agitation or baffling required

- low energy consumption

- simple structure

- good stability

- scaling up capabilities

Antec goes where the waste is

Our solutions offer scalable production with a higher energy return, in one-third of the time compared to traditional systems. By building plants close to where biomass is produced, we minimize transportation costs and reduce our carbon footprint.

Operations that can go wherever the waste happens to be – from fish and animal offal to unused agricultural biomass.

Waste to energy

A medium-sized plant of 10 reactors can turn average 55 000 tonnes of organic waste into renewable energy.

Different substrates

Our technology can handle various mixes of feedstock. Food waste, fish ensilage, fish sludge, and manure.

Scaling opportunities

Our modulardesign, off-site construction process, and low area use make it easy to scale your production.

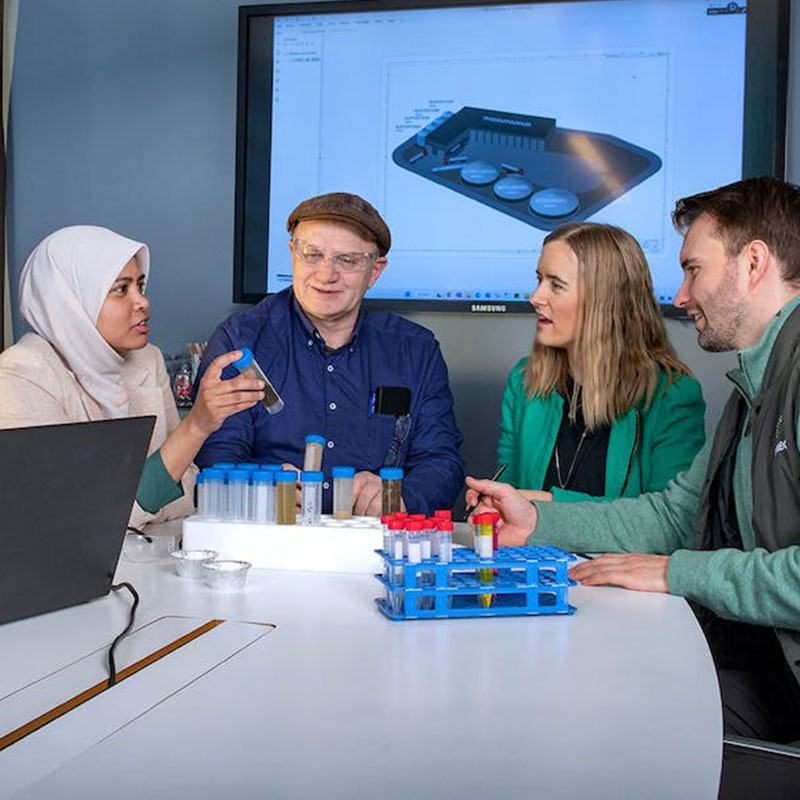

Operations support and biological advisory

Remote monitoring

We offer remote monitoring solutions that ensure optimal production and high reliability with limited local operations teams.

Operations support and biological advisory

Our in-house biology advisory team tracks performance providing peace of mind and maximum productivity. That’s how we can ensure operational stability, ease of maintenance, no sedimentation, and no downtime.

How it works

Our technology is focused on scalability and high-energy outcomes. Embark on the journey from waste to value.